HEPA Filter Integrity Test: Procedure, Acceptance Criteria & Frequency

If you operate a critical environment, you understand that "clean" is not a feeling—it is a measurable state of control. The HEPA filter integrity test is the definitive validation method used to prove that your filtration system is protecting your product, your people, and your research from airborne contaminants.

Whether you manage a sterile compounding pharmacy in Atlanta, GA, a semiconductor plant in Alpharetta, or a biosafety lab in Athens, professional HEPA filter testing and certification is your primary defense against regulatory non-compliance. It moves you from assuming your air is clean to proving it with hard data.

In this comprehensive guide, we will break down the practical hepa filter integrity test procedure, the specific acceptance criteria required by ISO and FDA standards, and the guidelines that dictate your hepa filter integrity test frequency.

What is a HEPA Filter Integrity Test?

A HEPA filter integrity test (often referred to in the field as a leak test or dispersed oil particulate test) is a non-destructive validation process. Its purpose is to confirm that the entire filtration system is sealed and functioning according to design specifications.

It is important to understand that this test does not measure the efficiency of the media (that is done at the factory). Instead, the integrity test of hepa filter systems verifies the installation. We are looking for bypass leakage—unfiltered air slipping through:

- The filter media itself (due to shipping or handling damage).

- The gasket seal or gel seal connecting the filter to the housing.

- The filter frame and support structure.

- The HEPA filter housing joints.

Why "Integrity" Matters

In ISO Class 5, 7, or 8 environments, airflow is designed to sweep contaminants away. If there is a breach in the integrity of hepa filter seals, dirty air from the plenum can bypass the filter and enter the critical zone. This is why validation of hepa filter systems is a mandatory step in certification for industries ranging from pharmaceuticals to aerospace.

Industry Note: "We often find that failures occur not in the expensive filter media, but in the simple gasket seal. A $10 fix can save a $100,000 batch of product."

HEPA Filter Integrity Test Procedure (DOP vs. PAO)

When facility managers search for the hepa filter integrity test procedure, they often encounter confusing acronyms like DOP and PAO. While the chemistry has changed, the physics of the scan test remain constant.

1. The Challenge Agent: DOP vs. PAO

Historically, DOP (Dioctyl Phthalate) was the industry standard liquid used to create the test aerosol. You will still hear veteran technicians refer to a dop hepa filter integrity test or search for dop test for hepa filter.

However, DOP was identified as a potential carcinogen. Today, the modern standard is the PAO hepa filter integrity test. PAO (Poly-Alpha Olefin) is a safer, non-carcinogenic substitute that behaves almost identically during testing. If you request a hepa filter pao test, you are asking for the modern, safe equivalent of the traditional DOP method.

2. Pre-Test Verification (Airflow)

Before any aerosol is released, we must perform an air velocity test for hepa filter units.

- Why? The challenge aerosol needs to be distributed evenly. If the airflow velocity is too low or turbulent, the upstream concentration will not mix properly.

- The Check: Technicians verify that air volume and velocity match the original design specs (typically around 90–100 fpm for laminar flow units).

3. Establishing Upstream Concentration

Reliable data depends entirely on a stable hepa filter integrity test upstream concentration. We use an aerosol generator to introduce the PAO mist into the airstream upstream (before) the filter.

- The Baseline: We measure this cloud using an aerosol photometer. We calibrate the instrument to read this upstream cloud as "100%."

- Stability: If the upstream concentration fluctuates, the downstream reading will be invalid. A mixing distance of at least 10 duct diameters is usually recommended to ensure uniformity.

4. The Scanning Method (Probe Scan)

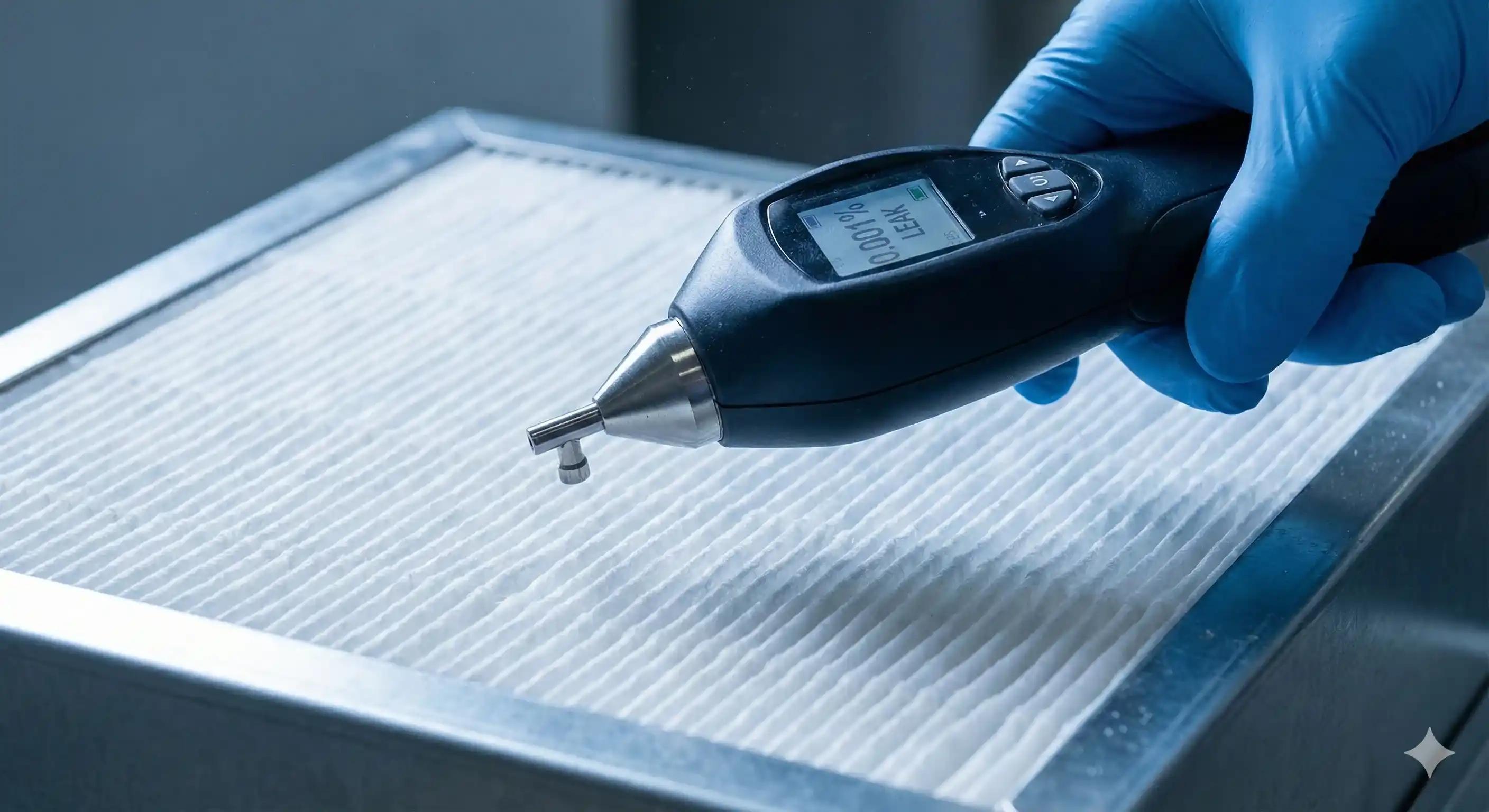

Once the upstream baseline is set, the technician moves to the downstream side (the clean room side). Using a handheld scan probe attached to the photometer, they scan:

- The Perimeter: Tracing the gasket seal or gel seal where the filter meets the housing.

- The Face: Scanning the entire face of the filter media in slightly overlapping strokes.

The probe must be held approximately 1 inch (25mm) from the face and moved at a speed of no more than 2 inches (50mm) per second. This slow pace ensures the photometer has time to detect even microscopic downstream leakage.

Acceptance Criteria: What Counts as a "Pass"?

Understanding hepa filter integrity test acceptance criteria is critical for your quality assurance team. You cannot rely on a generic "pass"; you must know the limit defined by your specific industry standard.

The specific hepa filter integrity test limit is defined by standards such as ISO 14644-3 and IEST-RP-CC034.

Different environments require different strictness levels. Below is a breakdown of the standard acceptance limits based on the application:

| Application / Standard | Filter Efficiency | Max Allowable Leakage (% Penetration) |

|---|---|---|

| Standard Cleanroom (ISO 14644-3) | 99.97% (HEPA) | 0.01% |

| Sterile Pharma (FDA / USP 797) | 99.99% (HEPA) | 0.01% |

| Semiconductor (IEST-RP-CC034) | 99.999% (ULPA) | 0.001% or lower |

| Nuclear / Biosafety (ASME N510) | 99.97% (HEPA) | 0.03% (for specific bank tests) |

The Logic: If the upstream cloud is "100%," the photometer should read "0.00%" downstream. If it reads 0.01% or higher at any distinct point, that is a significant leak.

Pharmaceutical Context: In FDA-regulated aseptic processing (Class 100 / ISO 5), this 0.01% criterion is strictly enforced. Even a momentary spike during the probe scan requires investigation.

HEPA Filter Integrity Test Frequency

How often should you validate? The hepa filter integrity test frequency is determined by risk assessment, manufacturer guidelines, and regulatory mandates (such as USP 797 for pharmacies).

1. Routine Schedule

For most critical environments, hepa filter integrity testing guidelines recommend testing at least annually (every 12 months). For highly critical zones (like surgical suites or sterile compounding), a semi-annual (every 6 months) schedule is standard practice to ensure patient safety.

2. "Event-Based" Retesting

You must trigger a retest after maintenance or specific events, regardless of the calendar schedule:

- Filter Replacement: Whenever a new filter is installed, it must be integrity tested immediately.

- Relocation: If a biosafety cabinet or laminar flow hood is moved on its casters, the seals can shift.

- System Repairs: Any work on the HVAC motors, plenum, or ductwork upstream of the filter.

- Failure Investigation: If your continuous particle monitoring shows a spike, an integrity test helps pinpoint the source.

HEPA Filter Integrity Testing Equipment

You cannot perform this test with a standard particle counter. HEPA filter integrity testing equipment is specialized hardware designed for high-concentration challenges.

- Aerosol Photometer: This is the core instrument. Unlike a particle counter that counts individual specs of dust, a photometer measures the mass concentration of the aerosol cloud. It provides real-time, analog feedback that allows the technician to "hear" and "see" the leak instantly.

- Aerosol Generator: These devices heat or shear the PAO liquid to create a polydispersed aerosol. For large air handling units, a thermal generator is used to produce enough smoke to challenge a massive filter bank.

- Scan Probe & Tubing: The interface between the technician and the filter.

Ensure your service provider uses equipment with valid calibration stickers. Using a photometer that hasn't been calibrated in two years renders the validation of hepa filter results void in the eyes of an auditor.

Common Failure Causes & What to Do Next

A hepa filter integrity test failure can be stressful, but in our experience across Georgia facilities, it is rarely a catastrophe. A failure simply means a leak was found; it does not always mean the expensive filter media is ruined.

Common Failure Points:

- Gasket Leaks: This is the #1 cause of failure. The neoprene gasket or gel seal may not be seated correctly against the hepa filter housing knife edge. Often, simply tightening the corner clamps can stop the leak.

- Frame Leakage: Small gaps in the grid system or housing joints where caulking has degraded over time.

- Installation Damage: This is the "oops" factor. If a technician touches the delicate media paper during installation, it can create a pinhole.

- Media Fatigue: Old filters can develop micro-cracks due to years of vibration and air pressure.

The Repair Process

If the leak is in the media, industry standards (like IEST) allow for limited patching using approved silicone, provided the patch covers less than 3% of the filter face area. However, for critical ISO 5 zones, many facility managers prefer to replace rather than patch to eliminate any doubt.

Serving Atlanta, GA: Localized High-Performance Testing

While the standards are global, the support should be local. Facilities in Atlanta, GA, and throughout the Southeast face unique challenges, from high humidity affecting HVAC loads to the strict requirements of the CDC and massive biotech growth in the region.

We support Georgia industries by providing rapid, ISO-compliant validation. Whether you manage a massive data center cooling array in Alpharetta or a precise compounding pharmacy in Midtown, our local presence means we can respond quickly to minimize your downtime.

When you choose a local partner, ensure they understand the specific hepa filter integrity testing guidelines relevant to your sector—be it hospital compliance, pharmaceutical manufacturing, or aerospace cleanrooms.

FAQ: Common Questions about HEPA Integrity

What is a hepa filter integrity test?

It is a validation process that challenges a HEPA filter with an aerosol (PAO) to identify leaks in the media, frame, or seals, ensuring the air remains clean.

How do you do a hepa filter integrity test?

Technicians inject a PAO aerosol upstream and scan the downstream face of the filter with a photometer to detect if any aerosol is bypassing the filter.

Integrity of hepa filter is tested by what method?

The most common method is the Aerosol Photometer Scan method (often called DOP or PAO testing) compliant with ISO 14644-3.

What is the difference between DOP and PAO HEPA testing?

DOP and PAO are the challenge liquids. DOP is the older, potentially hazardous chemical; PAO is the modern, safer substitute. The testing equipment and procedure remain virtually identical.

How often should you schedule hepa filter integrity test frequency?

Testing is typically required annually, but should also occur every 6 months for critical aseptic areas, or immediately after filter replacement.

What causes hepa filter integrity test failure?

Common causes include damaged filter media, dried-out or improperly seated gaskets, and leaks in the filter housing or frame.

What should a hepa filter integrity test report include?

It should list the test method, upstream concentration, percentage of penetration (leakage), equipment calibration data, and a clear pass/fail status.

Ensure Your Air is Clean and Compliant

A robust hepa filter integrity test program is the only way to prove your clean environment is actually clean. By understanding the procedure, acceptance criteria, and proper equipment, you can manage your facility with confidence.

Need certification you can trust?

If you require HEPA filter testing, certification, or troubleshooting in Atlanta, GA, or anywhere across the Southeast, Contact Us Today to schedule your validation.